| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | JK |

| Certification : | ROHS |

| Model Number : | CFR1/4W |

| Price : | Negotiable |

| Delivery Time : | 3-7 working days |

| Payment Terms : | T/T & Paypal |

| Supply Ability : | 200,000,000,000Pcs per month |

Quick Details

Carbon film resistors are a significant improvement on carbon

composition. However, in comparison to metal film and metal oxide

film, the commercially available range steadily decreases. Metal

and oxide film are not more expensive to produce, and have overall

better properties.

Description:

Carbon film resistors are a fixed form type resistor. They are

constructed out of a ceramic carrier with a thin pure carbon film

around it, that functions as resistive material.

Application

Typical use for carbon film resistors is in high voltage and

temperature applications. Operating temperatures are up to 15kV

with a nominal temperature of 350°C. Examples are high voltage

power supplies, radar, x-rays and laser.

Specification

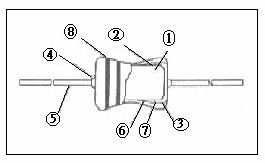

Structure diagram

The construction of resistor (CFR series) shall be as follows:

NO | Item | Material |

1 | Ceramic core | High alumina ceramic is used. |

2 | Resistor element | The resistor element shall consist of carbon film. |

3 | Terminal | Tinned iron cap. |

4 | Connection | The lead wire, which is plated with solder, shall be mounted to the caps by welding process. |

5 | Lead wire | Soldered or tinned annealed wire. |

6 | Undercoat painting | Electric insulation resin. |

7 | Finishing painting | Epoxy resin is used. |

8 | Indication | Color code. |

|

|

|

|

|

P type

Type | Dimensions | |||||

Normal Size | Small Size | I±2.0 | L±1.0 | ψD | ψd±0.05 | H±2.0 |

CF1/8W | CF1/4WS | 60 | 3.2 | 1.8±0.5 | 0.43 | 28 |

CF1/4W | CF1/2WS | 60 | 6.5 | 2.3±0.5 | 0.45 | 28 |

CF1/2W | CF1WS | 60 | 9.0 | 3.2±0.5 | 0.50 | 28 |

CF1W | CF2WS | 60 | 11.5 | 4.5±1.0 | ||

|